In the dynamic world of direct mail marketing, making a lasting impression while managing costs is key. With 75% of people recalling direct mail pieces they receive, and 73% of consumers preferring it for brand communication1, the choice of printing method is crucial for success. Dive into the nuances of shell and digital printing to discover how each can uniquely elevate your campaign’s effectiveness and efficiency.

But with so much material vying for consumers’ attention, how can you make sure your campaign stands out without breaking the bank on your printing budget? Choosing the right printing method can be a challenge. Let’s talk about two popular choices and the benefits and weaknesses of each: shell printing and digital printing.

Shell Printing

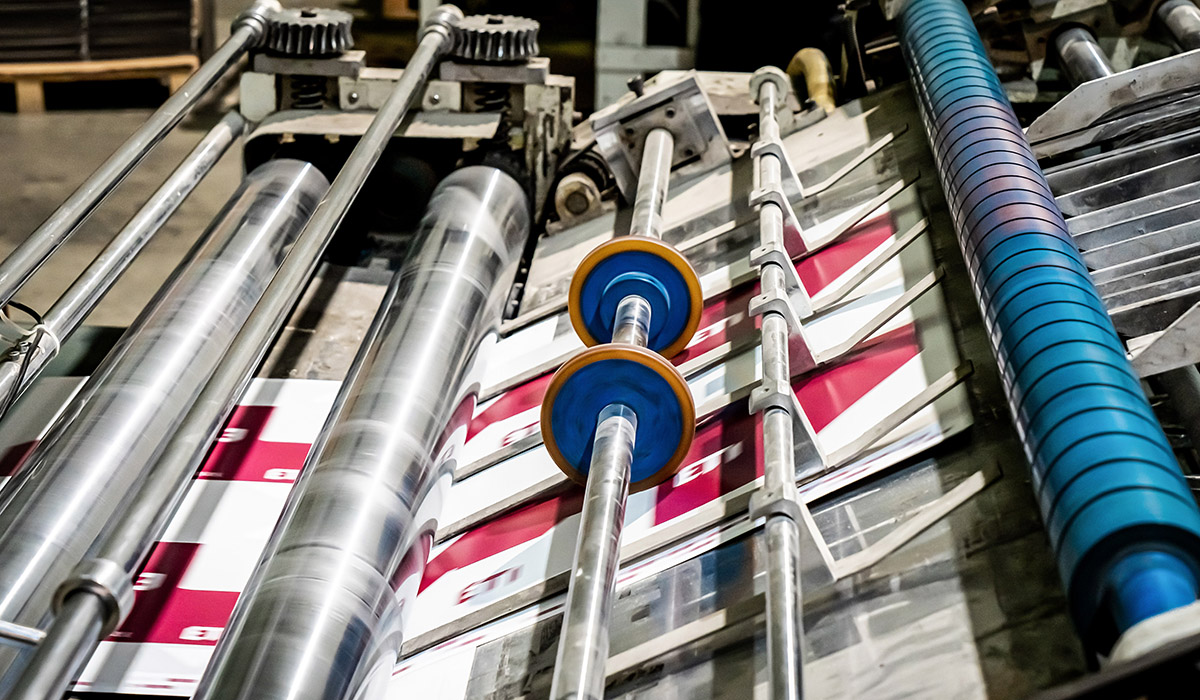

Shell printing involves creating a pre-printed “shell” that contains all the static elements of your direct mail piece, such as the logo, graphics, and background design. This shell is typically printed using offset printing, which is a cost-effective method for very large quantities (a couple million, for instance). Variable data, such as names, addresses, and personalized offers, are then printed digitally on top of the shell.

Pros:

- Cost-effective: Shell printing is generally more cost-effective than digital printing for high-volume campaigns. The initial cost of printing the shells is high because of the large quantity being created, but the per-unit cost decreases significantly for subsequent mailings.

- Faster setup: Once the shells are printed, it takes only minutes to print the variable data and assemble the mail pieces. This can be a significant advantage for businesses with tight deadlines.

- Inventory control: Shells can be pre-printed and stored, allowing businesses to react quickly to changes in the market or customer preferences.

- Personalization: Shell printing allows for a high degree of personalization, as variable data can be printed onto each individual piece.

Cons:

- High initial cost: As stated above, the upfront cost of printing the shells can be substantial, making it less suitable for small or infrequent mailings.

- Limited flexibility: Once the shells are printed, it is difficult to make changes to the static content.

- Storage requirements: Shells require storage space, which can be an issue for some businesses.

Digital Printing

Digital printing, on the other hand, is a one-step process that prints the entire direct mail piece directly from a digital file. This method allows for greater flexibility and customization, as each piece can be personalized with variable data. This means that there is no need to pre-print shells, and the entire printing process can be completed in a single step.

Pros:

- Flexibility: Digital printing offers a high degree of flexibility, as you can make changes to your content up to the moment of printing.

- Faster turnaround: Digital printing is often faster than shell printing, especially for smaller or variable-sized campaigns.

- No storage requirements: Since there are no shells to store, digital printing saves valuable space.

Cons:

- Higher cost: Digital printing is generally more expensive than shell printing for high-volume campaigns.

- Slower speed: Digital printers are slower than offset presses, which can be a bottleneck for large mailings.

- Limited personalization: While variable data printing is possible, it can be more challenging and costly than with shell printing.

The best printing method for your direct mail campaign will depend on a number of factors, including your budget, timeframe, and the complexity of your mailing. Here are some general guidelines:

Use shell printing for:

- High-volume campaigns

- Time-sensitive campaigns

- Campaigns with a high degree of personalization

Use digital printing for:

- Low-volume campaigns

- Flexible campaigns where you need to make changes to your content frequently

- Campaigns with limited storage space

Both shell printing and digital printing have their own advantages and disadvantages. By carefully considering your specific needs and budget, you can choose the right printing method to ensure the success of your direct mail campaign.

When choosing a printing partner, please make sure they can offer you both options (many printers do not). The true measure of a properly equipped production environment is its responsiveness to the full spectrum of customer requirements. Your printer needs to grow with your business to get the best product for your specific needs at any given time, for any given campaign. At ABS Graphics we are a one-stop for virtually any type of printing, plus a full gamut of services. Reach out to us anytime to learn how we can help you in your direct mail planning.

[1] https://www.dataaxleusa.com/blog/direct-mail-statistics/